Blackline Safety is a technology leader driving innovation in the industrial workforce through IoT (Internet of Things). With connected safety devices and predictive analytics, Blackline enables companies to drive towards zero safety incidents and improved operational performance. Blackline provides wearable devices, personal and area gas monitoring, cloud-connected software and data analytics to meet demanding safety challenges and enhance overall productivity for organizations with coverage in more than 100 countries. Armed with cellular and satellite connectivity, Blackline provides a lifeline to tens of thousands of people, having reported over 200 billion data-points and initiated over seven million emergency alerts. For more information, visit BlacklineSafety.com and connect with us on Facebook, Twitter, LinkedIn and Instagram.

Tech Breakthrough in Single-Gas Detection for Shutdowns and Turnarounds.

Blackline Safety, Leader in Connected Gas Detection & Lone Worker Safety

September 07, 2022

We’ve all come to expect personal tech like our cell phones to advance with every update and, occasionally, for a major breakthrough to occur. The addition of touchscreens in 1992 – giving birth to the first “smartphone” - was one of them. Safety technology is no different but gas detection for shutdowns and turnarounds hasn’t seen a significant breakthrough in a very long time. That has now changed.

We’ve all come to expect personal tech like our cell phones to advance with every update and, occasionally, for a major breakthrough to occur. The addition of touchscreens in 1992 – giving birth to the first “smartphone” - was one of them. Safety technology is no different but gas detection for shutdowns and turnarounds hasn’t seen a significant breakthrough in a very long time. That has now changed.

When it comes to single-gas detectors for short-term projects in the oil and gas industry, the reality is that traditional throwaway, beep-and-flash devices that only last two years are the equivalent of a flip-phone and do not measure up to best practices in the era of IIoT. 70% of organizations are working on their digital transformation strategy with a high priority set on improving operational efficiency. Using long-life connected single-gas detectors adds value with the opportunity to analyze data collected by the device to find areas to increase productivity and safety.

Connected wearable gas detectors now provide indispensable benefits like real-time remote alarms, 24/7 safety monitoring, and emergency dispatch. Not only that—connected safety solutions also deliver vital data that streamlines your incident response and lets you take proactive actions to prevent them—all while improving compliance and operational efficiency.

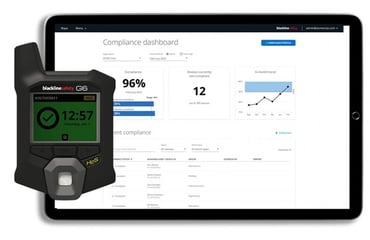

If you’re concerned about cost, new wearable connected devices like Blackline Safety’s G6 have arrived on the market to provide higher safety at a reduced total cost of ownership (TCO) over their lifespan – ensuring both peace of mind and long-term value.

Real-Time, Informed Safety

Worker safety is at its highest vulnerability during a shutdown or turnaround. With an increased number of confined space entries, various nonroutine tasks being performed and an increased number of personnel onsite including contractors unfamiliar with the facility. Worker safety needs to be a primary focus.

Almost 50% of work-related accidents in plants occur during plant maintenance outages. (TA Cook and Solomon Associates 2019)

Safety can be improved by switching from disposable to connected single-gas detectors. Instead of only notifying the wearer of atmospheric risks, connected devices also notify safety monitoring personnel who may even be located off-site. This empowers them to take immediate action when an alarm occurs so they can alert nearby workers who may also be at risk.

Safety can be improved by switching from disposable to connected single-gas detectors. Instead of only notifying the wearer of atmospheric risks, connected devices also notify safety monitoring personnel who may even be located off-site. This empowers them to take immediate action when an alarm occurs so they can alert nearby workers who may also be at risk.

Instead of waiting for devices to be docked by workers or contractors during a shutdown or turnaround, alarm data from connected wearables is received in real-time, putting safety information at safety manager’s fingertips. Supervisors can see and assess gas levels and know exactly where and when an incident occurred to make quick, informed decisions and ensure the project stays on track. Real-time data means real-time response.

Sensor drift is the natural tendency of a sensor’s performance to degrade over time as its components age. This is an undeniable fact for electrochemical sensor technology. (ISHN 2017)

New connected single-gas monitors also have more accurate gas detection capabilities. Since electrochemical sensors can drift over time, with some estimates of up to 20% loss of sensitivity per year (analog.com) they need to be calibrated to adjust gas readings, but disposable detectors simply don’t have that functionality. Two-year detectors also don’t monitor for short-term exposure limits (STEL), potentially putting worker health at risk.

Data-Driven, Preventative Safety

Beyond rapid incident response, connected wearables provide safety management personnel with invaluable data, such as real-time, quantitative alarm notifications with time, location, and gas exposure levels. The software then collates and displays the device data in summarized reports. With easy-to-interpret graphs and charts, these reports provide safety management personnel a birds-eye-view into full fleet device usage, compliance status and gas exposures. The data also provides a detailed view into which individual devices are being properly used, bump tested and calibrated, putting the accountability and responsibility of maintenance and compliance in workers’ hands. In the case of alarms, because the information is delivered directly from the devices to a centralized dashboard, there’s no need to rely on workers and contractors to report their exposures.

Reduced Cost of Ownership

Beyond initial hardware price and costs associated with maintenance (e.g., calibration gases), several factors contribute to the final TCO of a gas detection program for a shutdown or turnaround.

A major contributor to sunk costs in gas detection is lost devices. On average, 20% of a fleet needs to be replaced because devices are lost or misplaced (Priority Metrics Group). This means carrying extra inventory of disposable devices. In contrast, connected devices can easily be located via GPS tracking so they can quickly be found.

80% of all turnarounds are over budget by more than 10%.

(TA Cook and Solomon Associates 2019)

Device turnover is an additional load on TCO. Disposables last around two years before they’re discarded, while connected single-gas devices like G6, are rechargeable and can last four years (one year per charge).

They also have direct-to-cloud connectivity right out of the box. Much like your smartphone, this enables automatic, over-the-air updates with the latest features and enhancements. So, instead of a static throwaway that becomes out of date during its use, connected devices continuously improve over their lifespan as new features are added and firmware is automatically updated.

Summary

Best safety practices for shutdowns and turnarounds have recently evolved dramatically, and digital transformation is helping to meet the needs of the oil and gas industry. The “canary in a coal mine” approach of using disposable, beep-and-flash single-gas detectors no longer address the goals of safety programs. Connected devices with supporting software have emerged that not only provide more precise gas exposure detection and detailed, real-time information to better protect workers and facilities, but they last longer and provide an all-in-one solution that reduces overall costs.

Get In Touch

Let’s start a discussion about your safety challenges and needs.

Related Blog Posts

EXO Detects Underground Danger

April 04, 2025

It started with a strange sight—bubbling groundwater just outside the offices of Blackline Safety channel partner Aegis Safety in Brisbane,...

Real-life Incident: Lieutenant Anderson II’s Story – The Silent Killer

February 25, 2025

‘The absolute worst atmosphere I've seen': How G6 alerted first responders to lethal CO levels The scene that greeted firefighters as they...

Real-life Incident: Anna’s Story – Heart Attack While Working Alone

January 22, 2025

‘Please hurry!’How Anna’s G7 Saved Her Life Pain ripped through Anna’s chest and back, taking her breath away. She felt dizzy and like she was...