Ted Gibson has had a prolific safety career with close to 20 years of experience protecting the health and well-being of workers in the oil and gas industry in Canada and the U.S. He has extensive knowledge of the intricacies and challenges of various oil & gas and petrochemical operations with a specific focus on shutdowns and turnarounds, having planned and scheduled the execution of over 250 projects. His expertise has been critical in project management, strategic planning, multi-facility management, and emergency planning for companies such as Shell, Chevron, Exxon Mobil and Valero.

Top Five Hazards for Gulf Coast Oil and Gas Workers – And How to Mitigate Them

Ted Gibson, Strategic Sales Director, Refining & PetroChem

April 20, 2023

The oil and gas industry is an essential sector that provides the energy the world needs and powers global economies. But securing that energy can carry a high risk of occupational hazards.

The fatality rate in oil and gas extraction has been seven times higher than the average for US workers (CDC) and has around 100 deaths per year and an additional 1,400 non-fatal incidents. But even those high numbers may be underreported (Energy News Network).

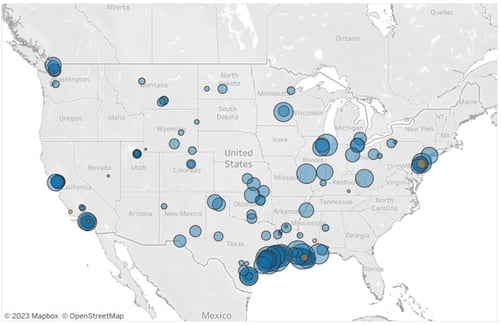

If we take a closer look at upstream rig counts, the four major US oil fields are in the PADD 3 region accounted for 74% of the 758 active drilling rigs in the US in March 2023 (Appx. 1). On the downstream side, of the 17.3 million barrels per day of refinery capacity in the US, 44% of that is located relatively close to the Gulf Coast, including 8 of the 10 largest refineries (Appx. 2). And midstream is answering the demand with 169 projects starting between 2021 and 2025 (Pipeline & Gas Journal).

If we take a closer look at upstream rig counts, the four major US oil fields are in the PADD 3 region accounted for 74% of the 758 active drilling rigs in the US in March 2023 (Appx. 1). On the downstream side, of the 17.3 million barrels per day of refinery capacity in the US, 44% of that is located relatively close to the Gulf Coast, including 8 of the 10 largest refineries (Appx. 2). And midstream is answering the demand with 169 projects starting between 2021 and 2025 (Pipeline & Gas Journal).

This means a heavy majority of oil and gas workers at risk in the US are in the Gulf Coast / PADD 3 regions.

These oil and gas workers face considerable safety challenges every day. Many work alone or in remote locations. For example, rig crews, well operators, tanker truck drivers and many others, work with dangerous machinery and around deadly gases while separated from others. In addition to gas exposure concerns, downstream facility workers encounter elevated risks during shutdowns and turnarounds, evacuations, and confined space entries. Layering in the unpredictable Gulf Coast weather further increases the possibility for incidents.

In this article, we’ll review the top five hazards for Gulf Coast oil and gas workers and how to mitigate them with connected safety technology.

1) Exposure to Hazardous Gases or Unsafe Oxygen Environments

Gas detection is a critical safety requirement in the oil and gas industry, as many of the operations involve the handling of combustible gases, such as hydrogen sulfide (H2S), methane (CH4), and propane (C3H4). These gases are highly flammable, and in the case of H2S, can be deadly if inhaled at high concentrations.

Another high-risk atmospheric condition, often coupled with the presence of H2S, comes from the displacement or consumption of oxygen. Various conditions and processes can cause oxygen deficiencies such as oxidation from rusting, consumption from open flames or displacement by other gases. Highly explosive atmospheres can also occur in oxygen-enriched environments during refining processes or various situations like leaky torch hoses.

That’s why it’s imperative that oil and gas operations use connected gas detectors that can deliver:

- Real-time visibility -Traditional gas detectors only alert workers in the immediate vicinity. With connected gas detectors, monitoring personnel will automatically be notified of a gas exposure with real-time gas levels and the location so they can initiate safety procedures.

- Compliance management – Improperly maintained gas detectors are a challenge for oil and gas industry workers, which can lead to false alarms and inaccurate readings. To prevent this, it’s essential to properly calibrate and bump test gas detection equipment on a regular schedule. Connected gas detectors allow safety managers to visualize and verify the real-time compliance of the entire fleet. This information can indicate potential risks and encourages worker accountability to bump and calibrate on a regular basis.

- Reporting and analytics – Comprehensive reporting and data analysis assists with device compliance management and highlights trends to help improve safety measures. For example, a low-level gas reading consistently shown at the same location can indicate a slow leak or faulty equipment, indicating areas for maintenance crews to conduct repairs before a safety incident occurs.

2) Confined Space Entries (CSEs)

CSEs - like those in storage tanks, mud pits, reserve pits and excavated areas around wells - present a variety of risks that can result in serious injury or death. Consider the two main types of hazards when evaluating worker safety during confined space entries:

- Atmospheric hazards - Confined spaces can contain toxic or flammable gases such as methane, H2S, or CO, which can be deadly if inhaled. These gases can accumulate due to poor ventilation, leaks from equipment, or the breakdown of chemical compounds. Connected gas detectors, like the G7 with pump, can be set to a pre-entry mode to measure gas levels before entering a confined space and then switched to diffusion mode to protect the worker while completing the necessary work. Contractors will also often use a personal monitor, like the G6 single-gas detector, for continuous monitoring of the space following entry. Also consider the benefits of personal gas detectors and area monitors with long battery life so the CSE work can be conducted over extended periods without having to swap out batteries or equipment.

- Physical hazards - In addition to atmospheric hazards, the cramped and dark nature of these spaces makes them difficult to navigate which can lead to slips, trips and falls. Layer in the hot and humid climate of the Gulf Coast and it makes the work environment even more challenging. Should an entry worker suffer an injury, it can be difficult to signal for help, but connected gas detectors with fall and no-motion detection can automatically notify monitoring personnel. Connected devices also enable two-way communication to rapidly convey details of an incident.

Whether from a dangerous atmosphere or the physical hazards within a CSE, with connected safety devices, workers can feel confident knowing their well-being is being monitored should an event occur.

|

Digital Confined Space Management (DCSM) System Brings New Levels of Safety and Efficiency |

3) Shutdowns and Turnarounds

During a shutdown or turnaround at a Gulf Coast oil or gas facility, there are additional hazards that HSE personnel and workers must be aware of to make sure safety is always a top priority. This includes significant added risks such as:

- Oxygen displacement and flammable or toxic gases released during the process of shutting down and restarting equipment for maintenance or repairs.

- Additional confined space entries under a short timeline

- Contractors new to the site who are unfamiliar with the facility and its specific safety procedures.

- Fatigue from longer hours and compressed timelines can put workers at greater risk

Depending on the work being conducted, supervisors and workers must know the potential hazards faced and be equipped with proper gas detection devices, whether that be a single-gas detector, like the Blackline’s G6, or a multi-gas detector, like the G7, to deliver live data on gas readings and the ability to quickly take emergency action if needed.

Almost 50% of work-related accidents in plants occur during plant maintenance outages.

(TA Cook and Solomon Associates 2019)

|

Shutdowns and Turnarounds: Four Key Considerations For Your Organization |

4) Evacuation Management

Evacuation Management is a big task for any oil and gas facility regardless of location, but the Gulf Coast has added challenges due to the region's susceptibility to hurricanes and tropical storms. When a major storm is forecasted, oil and gas companies must make quick decisions about whether to evacuate and shut down operations to ensure worker safety. The Gulf Coast region is also vast and complex, with a high number of facilities spread across a large area. This can make it difficult to actively communicate with employees and know their location during an evacuation.

Whether it be a weather hazard for the area or more localized risk due to a detected atmospheric hazard, connected wearable devices with integrated GPS location technology offer several benefits:

- Improved communications – The ability to send mass or targeted messages including real-time updates such as changing muster points

- Informed responses - Emergency responders will know:

- A missing worker’s precise location on an online map

- Details of the situation such as gas levels, fall detection or if a worker manually called for help

- Faster drills and evacuations

- GPS location visibility eliminates the need for time-consuming manual headcounts

- If a worker is missing, their exact location is known (no search party required), saving critical seconds if they need assistance

- Future improvements - Analyzing evacuation routes and times from drills can provide valuable insights to improve future emergency preparedness

Overall, the use of connected wearable devices with GPS location technology can greatly improve the efficiency and effectiveness of evacuation management and drills.

|

Leave No One Behind: How Connected Safety Technology Streamlines Evacuation Management |

5) Lone Worker and Transportation Hazards

A significant challenge for Gulf Coast oil and gas workers is lone worker safety. Lone workers are those who work alone or in remote locations without immediate access to colleagues or emergency services. In the oil and gas industry, this can include well-testers, pipeline inspectors, and maintenance workers but also refinery workers who may be temporarily out of direct contact with others.

Lone worker safety can be increased exponentially with connected safety devices that offer:

- Enhanced connectivity-- Due to the remote location of some rigs and facilities, the lack of reliable cellular coverage is an additional risk factor. In these environments, safety devices with satellite connectivity, like the G7x, ensure workers always have an accessible lifeline for help should they need it, for example, if they are stranded, or if they slip, trip or fall and suffer an injury.

- Integrated location technology—Devices with GPS provide location information so a worker’s exact coordinates can be known if they need assistance.

- Emergency SOS latch—can be pulled by the device wearer to call for help in the event of an emergency.

- Sensors for fall and no-motion detection—Detect if a device wearer slips, trips or falls and can send an automatic alert to notify monitoring personnel.

- Missed check-ins—Devices identify when a team member misses a scheduled wellness confirmation.

- Two-way communications—Text messaging and two-way voice communications (like a walkie-talkie) ensure workers are always connected.

Vehicle accidents or being struck by an object or equipment accounts for two-thirds of worker fatalities (CDC). All oil and gas workers need an easy way to call for help should an incident occur, regardless of their location.

|

Safety For Your Most Vulnerable, Remote and Lone Oil and Gas Workers |

Summary

Oil and gas workers in the Gulf Coast face numerous safety challenges every day on their worksites. From lone workers who can experience slips, trips, and falls to incidents with large equipment or vehicles without an easy option to call for help. In addition, many processes such as CSEs and shutdowns and turnarounds can present hazardous gases or unsafe oxygen environments. The weather events in the Gulf Coast region can add another layer of complexity to incident management and evacuations. Connected safety devices can help mitigate these issues by providing real-time insight, reliable communication and comprehensive data analytics and reporting— optimizing situations like evacuations and future-proofing the overall safety of a worksite.

For more information and additional resources, please visit our Gulf Coast Oil and Gas Safety page:

About the Author

|

Ted Gibson Strategic Sales Director, Refining & PetroChem Blackline Safety |

Ted Gibson has had a prolific safety career with close to 20 years of experience protecting the health and well-being of workers in the oil and gas industry in Canada and the U.S. He has extensive knowledge of the intricacies and challenges of various oil & gas and petrochemical operations with a specific focus on shutdowns and turnarounds, having planned and scheduled the execution of over 250 projects. His expertise has been critical in project management, strategic planning, multi-facility management, and emergency planning for companies such as Shell, Chevron, Exxon Mobil and Valero.

Appendix 1

United States Rig Count - March 2021 (TCI)

|

Oil rig location |

Oil rig count |

|

Permian Basin |

353 |

|

Eagle Ford |

70 |

|

Haynesville |

67 |

|

Anadarko |

61 |

|

Appalachian |

51 |

|

Bakken Shale |

42 |

|

Niobrara |

39 |

|

Total |

758 (+13% Y/Y) |

Appendix 2

Top 10 U.S. Refineries Operable Capacity (U.S. Energy Information Administration)

|

Rank |

Corporation |

Company |

State |

Site |

Barrels per day |

|

1 |

Saudi Aramco |

Motiva Enterprises LLC |

Texas |

Port Arthur |

626,000 |

|

2 |

Marathon Petroleum Corp |

Marathon Petroleum Co LP |

Texas |

Galveston Bay |

593,000 |

|

3 |

Marathon Petroleum Corp |

Marathon Petroleum Co LP |

Louisiana |

Garyville |

585,000 |

|

4 |

ExxonMobil Corp |

ExxonMobil Refining and Supply Co |

Texas |

Baytown |

560,500 |

|

5 |

ExxonMobil Corp |

ExxonMobil Refining and Supply Co |

Louisiana |

Baton Rouge |

520,000 |

|

6 |

BP PLC |

BP Products North America Inc |

Indiana |

Whiting |

435,000 |

|

7 |

PDV America Inc |

Citgo Petroleum Corp |

Louisiana |

Lake Charles |

418,000 |

|

8 |

ExxonMobil Corp |

ExxonMobil Refining and Supply Co |

Texas |

Beaumont |

369,024 |

|

9 |

Marathon Petroleum Corp |

Tesoro Refining and Marketing Co |

California |

Carson |

363,000 |

|

10 |

Chevron Corp |

Chevron USA Inc |

Mississippi |

Pascagoula |

356,440 |

Get In Touch

Let's start a discussion about your safety challenges and needs.

Related Blog Posts

EXO Detects Underground Danger

April 04, 2025

It started with a strange sight—bubbling groundwater just outside the offices of Blackline Safety channel partner Aegis Safety in Brisbane,...

Real-life Incident: Lieutenant Anderson II’s Story – The Silent Killer

February 25, 2025

‘The absolute worst atmosphere I've seen': How G6 alerted first responders to lethal CO levels The scene that greeted firefighters as they...

Real-life Incident: Anna’s Story – Heart Attack While Working Alone

January 22, 2025

‘Please hurry!’How Anna’s G7 Saved Her Life Pain ripped through Anna’s chest and back, taking her breath away. She felt dizzy and like she was...