Blackline Safety is a technology leader driving innovation in the industrial workforce through IoT (Internet of Things). With connected safety devices and predictive analytics, Blackline enables companies to drive towards zero safety incidents and improved operational performance. Blackline provides wearable devices, personal and area gas monitoring, cloud-connected software and data analytics to meet demanding safety challenges and enhance overall productivity for organizations with coverage in more than 100 countries. Armed with cellular and satellite connectivity, Blackline provides a lifeline to tens of thousands of people, having reported over 200 billion data-points and initiated over seven million emergency alerts. For more information, visit BlacklineSafety.com and connect with us on Facebook, Twitter, LinkedIn and Instagram.

Four Educational Blackline Safety Webinars to Attend This Fall!

Blackline Safety, Leader in Connected Gas Detection & Lone Worker Safety

November 02, 2021

We’ve got four excellent webinars coming up this fall exploring themes around connected safety. Tune into one – or all – to learn more about how location-enabled smart technology and connectivity are bringing gas detection and emergency and incident responses to the next level. Here’s what’s coming up:

Optimizing Fire and Hazmat Response with Connected Safety Technology

Fire and Hazmat teams –and those who lead them –are faced with a host of challenges when responding to an incident. But rapidly advancing connected safety technologies can help optimize responses, disrupting what has been standard procedures for decades.

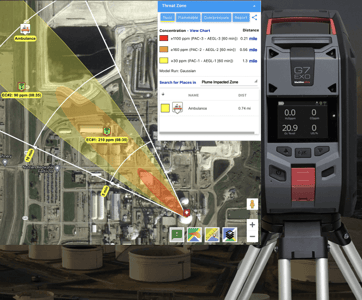

Watch the recording of our panel discussion on Optimizing Fire and Hazmat Response with Connected Safety Technology originally aired on Wednesday, Nov. 10 at 1 p.m. EST to hear from top industry professionals to learn how cloud-connected gas detection devices can:

- Give you full situational awareness, including real-time visibility of your people and facilities

- Incorporate plume modelling to help plan for, respond to, analyze and model chemical, fire and explosion events—anytime, anywhere on any device

- Deliver powerful analytics and reporting to help you make better decisions to predict and prevent incidents

SPEAKERS

- Rich Harlan, Industrial Emergency Council

- Steve Curry, Instructor, FEMA - Center for Domestic Preparedness

- Bobby Salvesen & Mike Monaco, Podcasters, The HazMat Guys

- Doug Mayer, Business Development Specialist - Fire and Hazmat, Blackline Safety

Safer and More Efficient Shutdowns and Turnarounds Through Digital Transformation

Shutdowns, turnarounds and outages are critical projects in the oil and gas industry that present additional challenges for worker safety. And with production offline, there is a strong focus to get up and running again as quickly as possible to reduce lost revenue.

Join our Safer and More Efficient Shutdowns and Turnarounds Through a Digital Transformation webinar on Wednesday, Nov. 17 at 12 p.m. EST and learn to identify:

- What connected safety is, how it impacts these types of projects and how it is a considerable improvement from historical approaches.

- The safety challenges and risks associated with shutdowns, turnarounds and outages

- The higher degree of safety protection achieved through connected workers and software solutions

- Opportunities to increase project efficiency

SPEAKERS

- Yves Carrier, Business Development Director, Blackline Safety

- Jousha Barnill, Regional Sales Manager - Houston, TX, Blackline Safety

Monitoring Everyday Exposure to VOC Gases – Protecting Your Workers Against Hidden Hazards

One worker dies every 30 seconds due to exposure to toxic gases in the workplace (UN Report, 2019). Can you be sure you are keeping your people safe by effectively monitoring their air quality?

Volatile organic compound gases (VOCs) are present in everyday life and can be harmless. Some however, are not, and can be hazardous to both employees’ health and the environment.

Join our webinar Thursday, Nov. 18 at 10:30 am UTC (5:30 am EST – the recording will be available to view here after the event) featuring industry-leading specialists in photoionization detection (PID) technology Ilaria Tramelli and Peter Morris, along with Blackline Safety connected safety monitoring pro, Miriam O’Connell.

You’ll discover:

- What VOCs are and where they are likely to show up in the workplace

- The potential health and environmental effects associated with both short- and long-term exposure to VOCs

- How VOCs can be effectively monitored through ION Science PID technology

- Ways cloud connectivity can support a data-driven safety solution for VOC monitoring

SPEAKERS

- Kelly Rose, Editor, Health and Safety Matters

- Ilaria Tramelli, PID Specialist, Blackline Safety Europe

- Peter Morris, Business Unit Manager, Sensors, ION Science

- Miriam O'Connell, Monitoring Services Supervisor, Blackline Safety Europe

Supporting Digital Transformation Through Connected Safety Technology

Across industrial and commercial sectors, the Industrial Internet of Things (IIoT) is changing how enterprises approach employee safety, health, performance, and quality. Cloud-connected personal protection wearables can deliver comprehensive real-time safety for at-risk workers, including those working alone or in remote areas, near hazardous gases or in confined spaces.

No matter if it’s an injury, fall, health event or gas exposure, cloud-connected software helps monitoring personnel effectively manage every incident from receipt of an alert through to its resolution in the shortest time possible. And the connected wearables with embedded GPS tracking, help emergency crews quickly find an employee’s exact location with full visibility into the incident and what type of response is required.

Beyond real-time incident and response management, the power of data from connected safety technology is helping businesses drive improvements through worksite optimization, employee movement pattern analysis, HSE software integration, gas leak detection and more.

Learn about how connected workers and worksites can help you increase the safety and efficiency of your teams through digital transformation.

Join our webinar Wednesday, Dec. 8 at 2:00 pm EST to discover how:

- The safety and gas detection industry has evolved far beyond the beep and flash devices of the past

- A comprehensive safety ecosystem can protect your business with personal gas detection, lone worker safety and area monitoring – and optimize its effectiveness with leading analytics and live-monitoring software

- Real-time visibility and direct communication with connected workers can better protect them in response to incidents and evacuations

- Direct-to-cloud connectivity means data is immediately accessible and can provide up-to-date insights to inform better decision-making

SPEAKERS

- Yves Carrier, Business Development Director, Blackline Safety

Get In Touch

Let’s start a discussion about your safety challenges and needs.

Related Blog Posts

When Seconds Matter: Protecting Emergency Responders and the Public from Radiation

March 28, 2025

Picture the scene: a firefighter races to a dumpsite unaware that improperly disposed of radioactive materials are present. The Geiger counter at the...

Real-life Incident: Lieutenant Anderson II’s Story – The Silent Killer

February 25, 2025

‘The absolute worst atmosphere I've seen': How G6 alerted first responders to lethal CO levels The scene that greeted firefighters as they...

Cool Under Fire: How Blackline Safety is Transforming Emergency Response

June 26, 2024

Real-time data and advanced gas monitoring technology empower fire and hazmat teams to tackle the toughest emergencies with confidence As dangerous...