Blackline Safety is a technology leader driving innovation in the industrial workforce through IoT (Internet of Things). With connected safety devices and predictive analytics, Blackline enables companies to drive towards zero safety incidents and improved operational performance. Blackline provides wearable devices, personal and area gas monitoring, cloud-connected software and data analytics to meet demanding safety challenges and enhance overall productivity for organizations with coverage in more than 100 countries. Armed with cellular and satellite connectivity, Blackline provides a lifeline to tens of thousands of people, having reported over 200 billion data-points and initiated over seven million emergency alerts. For more information, visit BlacklineSafety.com and connect with us on Facebook, Twitter, LinkedIn and Instagram.

How Connected Safety is Transforming the Workplace

Blackline Safety, Leader in Connected Gas Detection & Lone Worker Safety

March 04, 2021

Wearable connected technology has become commonplace in our personal lives from tracking our Uber’s location on our phone to checking the monitor on our wrists for our heart rate – and it’s changing industrial safety protocols as well. Environmental Health and Safety (EHS) is also going through an evolution in incident detection, avoidance, reporting, and management through the rise of connected safety in the workplace. Connected gas detection devices can help avoid serious workplace incidents. With around “340 million occupational accidents and 160 million victims of work-related illnesses annually”, according to the International Labour Organisation, we can do better.

Wearable connected technology has become commonplace in our personal lives from tracking our Uber’s location on our phone to checking the monitor on our wrists for our heart rate – and it’s changing industrial safety protocols as well. Environmental Health and Safety (EHS) is also going through an evolution in incident detection, avoidance, reporting, and management through the rise of connected safety in the workplace. Connected gas detection devices can help avoid serious workplace incidents. With around “340 million occupational accidents and 160 million victims of work-related illnesses annually”, according to the International Labour Organisation, we can do better.

It’s modern technology that gives real-time, data-driven insights into your safety on the ground, allowing for quick and informed decisions to protect worker lives.

What is connected safety?

A connected safety solution is comprised of a cloud-based software platform that connects to worker and workplace Internet-of-Things (IoT) safety-based devices to display data in real-time.

It’s Industrial IoT (IIoT) with a safety focus, with IIoT being a key competitive market differentiator and one of the main technologies underpinning what’s termed Industry 4.0.

“Industrial IoT (IIoT) refers to a network of interconnected devices used for designing, maintaining, monitoring, optimizing, and analyzing the industrial operations to gain real-time insights and make effective decisions.” - Industrial IoT (IIoT) Market Worth $263.4 billion by 2027

In the context of gas detection, this means progressing from simple monitors with only personal alarms to a cloud-connected network of devices that can be a mix of wearable gas detectors and area monitors. Data flows into smart, cloud-based software for analysis and reporting with the ability to communicate safety information back to devices by monitoring personnel. This results in a fully managed network of incident alerting, response, and avoidance opportunities across your entire workforce and sites.

This data-driven approach is revolutionizing industrial EHS, leading to improvements in worker safety, workflow, safety process automation, and heightened compliance.

A connected safety configuration for gas detection

IoT devices in a connected safety solution for gas detection range in functionality.

Blackline’s G7 Personal Gas Monitors transmit gas and location-based sensor information directly to our cloud-based platform. It provides instant alerting safety information and has two-way communications functionality over satellite and cellular networks.

The cloud-based software platform, in our case, the Blackline Live portal provides insightful data analytics with visualization dashboards, real-time visibility into incidents, and drill-down capabilities so you can monitor the safety of each employee.

It allows for remote device configuration, alert profiles and emergency response procedures, time-stamped GPS locations (including floorplan-based monitoring), and flexible integration with other enterprise software products such as SAP to make a fully connected workplace.

The benefits of connected safety solutions

Full visibility in real-time to the safety status of all workers

No matter where your workers are, whether in a busy facility or in a lone worker situation at a remote site, with wearable devices and data dashboards you can monitor the safety status of every single employee anywhere in the world. You have the ability to protect workers anywhere with either cellular or satellite connections so they can stay safe no matter their location.

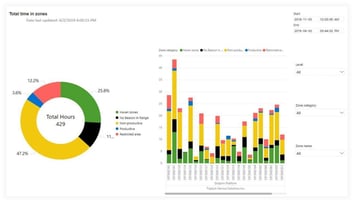

By clustering teams and sites, you gain real-time insights into gas exposure risks across any given workspace. And GPS tracking allows managers to track if workers haven’t reached a specific muster point and can connect to ensure no one gets left behind.

Leading indicators in the data allow for predictive and proactive safety

By using predictive models on your specific accumulated historical data across range of IoT devices, you’re able to identify patterns and thus key indicators to be able to forecast where and when incidents are more likely to occur.

By using predictive models on your specific accumulated historical data across range of IoT devices, you’re able to identify patterns and thus key indicators to be able to forecast where and when incidents are more likely to occur.

By early proactive analysis, you’re able to change procedures, behaviours, and responses quickly to avoid incidents. This reduces downtime in the case of planned events like turnarounds and shutdowns and for unforeseen events like potential gas leaks.

Streamlines safety processes

With connected safety solutions, you gain access to real-time data that can help enhance worker protection, in addition to fulfilling standard gas detection requirements. By eliminating manual data uploads and automating reporting, there is no delay in accessing data and no human-fallible link in the measuring

and reporting process. And with real-time data, help can be dispatched with full awareness of what risks are present so they arrive prepared to handle the situation.

Compliance reporting in real-time

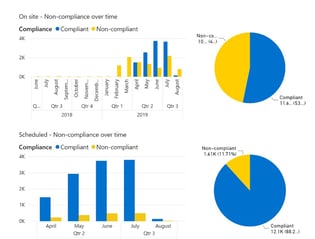

Industry regulatory compliance in safety and audits can cause nervous headaches for managers. With a connected safety  solution in place, you gain full confidence you are compliant with industry regulations at all times and have visibility to the current bump and calibration status of all devices.

solution in place, you gain full confidence you are compliant with industry regulations at all times and have visibility to the current bump and calibration status of all devices.

Connected safety allows you to see which workers are using non-compliant devices based on your organization’s bump and calibration procedures and take corrective action to ensure they stay safe.

With IoT device firmware and settings automatically updated without needing to dock devices, this means they are always up-to-date and up to code.

Worksite efficiency

IoT cloud-connected devices don’t only help with worker safety. As they are GPS-location tracked, you can identify patterns in worker time and location, seeing where productivity improvements can be made. Custom reporting with your data can identify patterns, insights and opportunities for facility layout improvements, shift management changes, contractor behaviours, and  resource scheduling.

resource scheduling.

With data-driven analysis, site operators can make informed and insightful decisions to translate patterns into efficiency and digitally transform the workplace. In addition, because they are cloud-connected and automatically updated, there’s no downtime to manual dock the devices for required firmware changes.

Learn more about connected safety solutions

Do a deep dive into connected safety by watching a recording of our webinar, Connected Safety: A new era in gas detection. It will walk through the Blackline Safety solution and show how real-time monitoring, data science solutions and reporting across entire networks help small companies to large enterprises become safer and smarter in their operations.

Read Brendon Cook’s article in OH&S:

Five Reasons to Incorporate Connected Safety into Your Fall Protection Program

Ready to learn more?

Get In Touch

Let’s start a discussion about your safety challenges and needs.

Related Blog Posts

Real-Life Incident: Mason’s Story — High H2S Exposure

November 25, 2025

“Shortness of breath. Request EMS to the location.” How Real-Time Gas Detection Led to a Quick Save Exposure to toxic gases can go from a strange...

3 Creative Applications of Blackline Safety Technology

July 29, 2025

Designed for Safety. Adapted with Ingenuity. Blackline devices are built for tough jobs—gas detection, lone worker monitoring, real-time emergency...

Real-Life Incident: Superior Fire Department Drug Bust

July 28, 2025

G7 helpsHAZMATteam safely navigate Wisconsin's largest DMT lab When Superior Wisconsin Fire Department received the call, the situation was...